Sep 20, 2023 · The Leader in Seal Integrity. Genesis Packaging Technologies is a worldwide leader in the science and technology of Parenteral Vial Sealing and Residual Seal Force testing. We provide advanced vial sealing equipment for the packaging of critical injectable pharmaceutical products.

Jan 14, 2016 · The majority of parenteral drug products are manufactured in glass vials with an elastomeric rubber stopper and a crimp cap. The vial sealing process is a critical process step during fill&finish operations, as it defines the seal quality of the final product. Different critical capping process parameters can impact rubber stopper defects, rubber stopper compression, CCI but also crimp cap

Feb 27, 2020 · The new head had a smaller diameter than the generic head to resolve the variability in the seal length and the new head crimping angle was aligned with the 4R vial lip angle. The 4R crimping head was installed and crimping was validated with three consecutive water runs of 315, 315, and 500 vials.

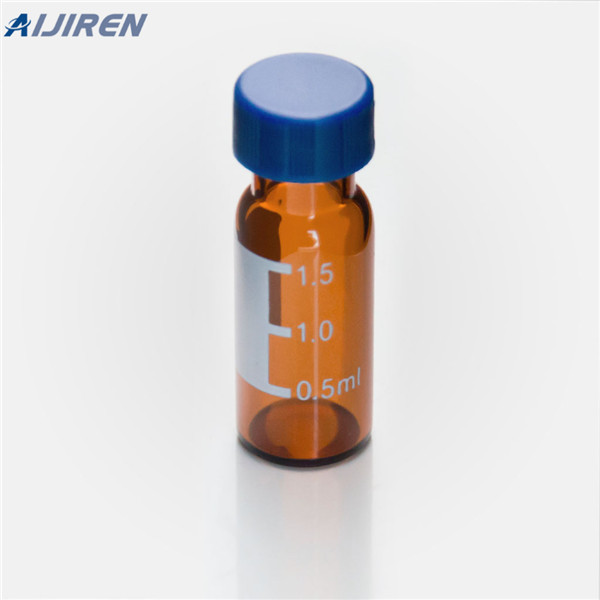

Use Thermo Scientific 11 mm Crimp/Snap Top Vials with snap caps or aluminum crimp seal closures. These high-quality 11 mm glass vials are 2 ml, 12×32 mm and fit most brands of autosamplers. Made of superior quality 33 expansion borosilicate clear Type 1, Class A or 51A Type 1, Class B amber glass, they meet all requirements of US, EU, and JPN Pharmacopia.Vials are available in all capacities

achieving the optimal seal compression when closing a vial. As an integral component of AVCS technology, SureStop vials offer the sealing and performance characteristics of a crimp top vial and the versatility and convenience of a threaded vial. This is achieved by incorporating a definite stop point into the design of the vial finish, preventing

Made of Type I Borosilicate Glass, SCHOTT Pharma´s vials offer high chemical resistance for the secure storage of liquid drug formulations. Their accurate dimensions and superior cosmetic quality ensure an efficient fill-and-finish process and secure container closure integrity. In addition, special features such as improved inner surfaces

Apr 11, 2022 · The right aluminum seal must be selected to hold the stopper flange and the vial at the land seal. The land seal is the compression seal formed between the stopper bottom flange and the top of the vial crown after crimping and is the primary sealing region for a vial-based system for the drug product shelf life.

Genesis Packaging Technologies, a division of R-V Industries, Inc., is a leader in the science and technology of pharmaceutical vial processing and handling. Purchasing equipment from Genesis offers customers support from a company with over 75 years of experience dealing specifically with vial handling equipment and technologies.

The Poly Crimp seal is versatile, working as either a snap-on or crimp-top cap. Simply use a standard crimping tool to secure the Poly Crimp seal onto any crimp-top vial. Ordering information: Choose preslit caps (available for some vials) to reduce the risk of needle bending, release vacuum from high-volume injections, and improve injection

Dec 1, 2017 · Disc-style crimping offers a more consistent, commonly used method. In this method, a pressure block applies an appropriate and uniform pressure onto the vial, stopper and seal. A disc then gently and consistently tucks the aluminum under the flange of the vial crown, securing the seal.

.jpg)

The vial sealing process is a critical process step during fill-and-finish operations, as it defines the seal quality of the final product. An adequate force to remove the f The majority of parenteral drug products are manufactured in a glass vials with an elastomeric rubber stopper and a crimp cap.

Clear 20 ml headspace vials designed to fit most headspace autosamplers.Vials are available in all capacities, materials like plastic vials or glass vials, and in a variety of colors to meet any collection, storage, or analysis need. Tailor vessels for specific media with various translucent manufacturing and different sterility options for precise test results. Choose from the extensive

Figure 1: Typical defects associated with the capping process (from left to right) partially crimped vials, glass crack, dimpling rubber stoppers, wrinkled crimp cap skirt. 1. Mathaes, R., et al., The pharmaceutical vial capping process: Container closure systems, capping equipment, regulatory framework, and seal quality tests, EJPB, 2015 2.

Vials and Crimping—Fully Automated Monitoring of Production Quality. Patient safety begins during the manufacturing of primary packaging for pharmaceutical products. It is important to be able to depend on technology that monitors the process chain in a reliable and cost-effective manner. Which is exactly what automated visual inspection (AVI

Feb 1, 2016 · The quality of the vial seal and the capping process can be characterized by two different types of tests. The CCI can be assessed by a variety of leak tests (described by Morton et al. [23]). The actual capping process can be characterized by several package seal quality tests. In this review we would like to focus on package seal quality tests.