Meet your certification and documentation needs with our Level 3 Thermo Scientific™ SureSTART™ HPLC and GC Certified Screw Vial and Cap Kits. Select Level 3 products for ultimate performance and sensitivity from your methods, while maintaining the highest levels of sample security and integrity. Choose from a variety of kits containing

container and closure systems’. The sample size is also not mandated but should be based on ‘informationand process knowledge’. If one equates ‘knowledge of the container, closure systems, and process’ to mean ‘data on the container, closure systems, and process’, one comes to the conclusion that scientific CCI studies

Jun 27, 2018 · Abstract. Capping completes the closure of parenteral drug products in the final packaging container and is critical in maintaining an integral seal to ensure product quality. Residual seal force

Sample Handling Products SureStop 9mm Vials Removing any subjectivity around achieving the optimal compression when sealing a vial. Analytical results are improved as a result of the elimination of evaporation differences between samples. PAGE 2-005 Virtuoso Vial Identification System A fast sample identity and security system that provides

Vial, SureStop Vial sealing a vial. Designed as a complete system, AVCS allows the closure, septum and vial to work together to prevent compression from exceeding the optimal range. This technical note will review the design features of AVCS and provide data to support how AVCS eliminates under/over compression of vial seals while improving

Dec 10, 2017 · in diameter to allow penetrat ion of the challenge microorgan ism under the conditions of the t est). For practical reasons most positive controls used in associat ion with the liquid immersion

Optimal Tightening Attempt, 9mm Closure Source C 0.040 0.030 0.020 0.010 0 0.050 Optimal Tightening Attempt, 9mm Closure Source D Sample Evaporation (g) 0.020 0.015 0.010 0.005 0 0.025 Normal Tightening, SureStop Vial/AVCS Closure Sample Evaporation (g) Sample Number 0.020 0.015 0.010 0.005 0.025 Crimp Seal Reference, Overcrimped Sample

Sep 30, 2016 · Understanding container closure integrity systems, reviewing past observations, and following the regulations and guidance documents are excellent ways to establish a compliant container closure integrity assay. This article describes recent changes to the United States Pharmacopeia (USP) , guidance documents, regulatory observations, common container closure methods, and provides

Sep 9, 2019 · Historically, probabilistic container closure integrity test methods such as water bath, dye, and microbial ingress tests have been used to determine package quality. These tests are limited in their effectiveness and reliability for several reasons. Chief among them are the subjectivity of the results, the lack of standardization, and the lack

Sep 2, 2019 · Container closure integrity (CCI) plays an important role in maintaining the sterility and stability of sterile injectable products. The defects that cause a sterile vial to leak are not necessarily detectable by a visual inspection process. Examples of such defects are those that are hidden by the crimp, microscopic cracks and scratches in the

single elastomeric closure type is dependent on the packaging/delivery system and may cover more than one functional parameter. A more complete discussion of fitness-for-intended-use testing, as compared to closure functionality assessment in early package development, is presented in Assessment of Elastomeric Closure Functionality in Injectable

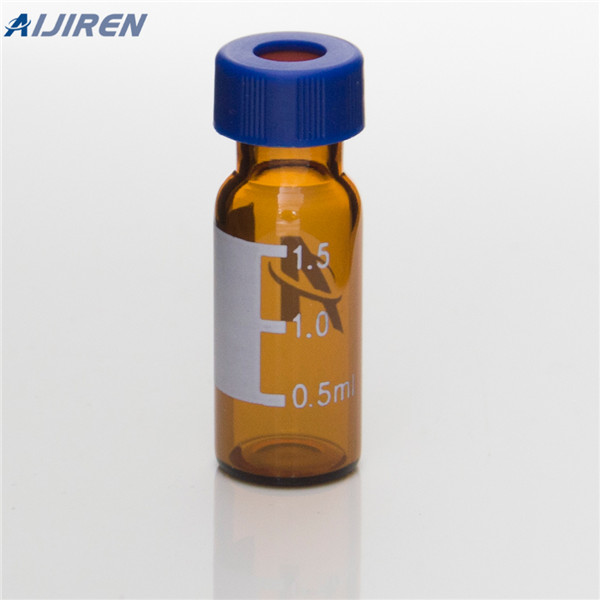

Explore all our special offers, all in one place. Temporary Price Reductions. Save with limited-time price reductions across select products and categories. View All Special Offers and Programs. Chemical Structure Search Help & Support. Fisher Scientific. Products. Chromatography. Autosampler Vials, Caps, and Closures.

For example, closure processing parameters and vial package sealing forces directly impact parenteral vial packaging integrity results. Plunger break and extrusion forces are directly related to the design, material of construction, and lubricity of the syringe barrel. Because closure functionality is connected to the packaging system, the

May 6, 2020 · For questions on the content of the guidance, contact CBER’s Office of Compliance and Biologics Quality at 301-827-3031; CDER’s Office of Pharmaceutical Science at 301-796-1228; CDRH’s

Feb 23, 2021 · Current trends in the pharmaceutical industry led to a demand for more flexible manufacturing processes with smaller batch sizes. Prepackaged nested vials that can be processed as a unit were introduced into the market to fulfill this need. However, vial nests provide a different thermal environment for the vials compared to a hexagonal packaging array and could therefore influence product