Jun 21, 2016 · The adapter has a spike at each end; one is inserted into the drug vial and the other container, first remove the protective cap from the IV is inserted into the injection port of the bag. The MiniBag Plus ® system (figure 16–3) uses a special container that has a vial adapter and a breakaway seal. The pharmacy is responsible for attaching

Vial Assembly) 2. Syringe unit (procedure: building the syringe unit) 1.4 Preparing one vial to one syringe Procedure: Note: Follow aseptic technique and local guidelines for safe handling of hazardous drugs, including the use of Personal Protective Equipment (PPE) and visual inspection. 4. Disengage syringe unit from Vial Assembly. Syringe unit is

For liquid pharmaceuticals, vials can be sealed within one line or immediately afterwards on a separate, compact machine. Our capping process easily meets the requirements of EU GMP Annex 1 – this is a groninger standard. groninger relies on the patented, very proven and low-particle single-disc sealing principle.

sealing of the container. The media is made to contact all product contact surfaces of the equipment chain, container closure, critical environment and process manipulations which the product itself will undergo. Media is then incubated and inspected for microbial growth. This information is

www.gen-techno.com

Sep 3, 2021 · A typical vial container closure system configuration has three major components: a vial, an elastomer stopper, and an aluminum seal with or without a flip-off button. 5 Among these container closure system components, the elastomer stopper plays a critical role by deforming to seal the vial-stopper interface area either temporarily or permanently.

Dec 15, 2020 · What is Hermetic Sealing? Hermetic sealing is the process of creating an airtight seal. Hermetic sealing can be done with plastics, epoxy resins, glass, metals, ceramics and more. There are many ways to create a hermetic seal, and even more applications. The specifics of what a hermetic seal is and what it’s for depends on the materials

When preparing a medication vial, wipe the rubber septum (or stopper) with a cotton swab or ball soaked with 60-70% alcohol. Do not touch, fan, or wipe off the disinfectant; allow the septum to air dry. Pierce the septum of the vial with a new and sterile syringe and needle. Insert air into the vial before drawing up the medication.

Dec 1, 2017 · Disc-style crimping offers a more consistent, commonly used method. In this method, a pressure block applies an appropriate and uniform pressure onto the vial, stopper and seal. A disc then gently and consistently tucks the aluminum under the flange of the vial crown, securing the seal.

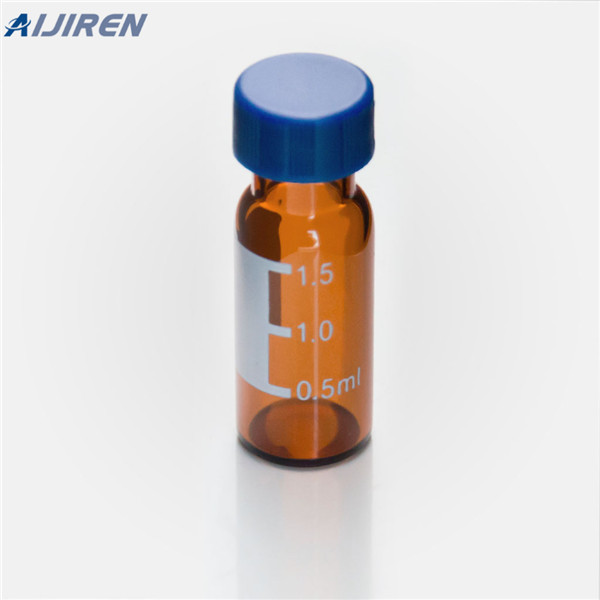

overtightened vials and for vials perceived to be optimally tightened and these were compared to losses from new vials designed to provide a definite sealing point. Test conditions • 1.3mL of pure methanol was added to each vial (always 50 in total) • All vials were incubated at a temperature of 40 °C for 72 hours

Remove the tamper-evident seal from the vial and wipe the rubber septum with an alcohol wipe. Allow to dry for 30 seconds. With the appropriate sized needle, draw into the syringe a volume of air equivalent to the required volume of solution to be withdrawn.

Testing Tips and Tricks. Reducing variability when testing residual seal force can be difficult to control. Since elastomeric vial seals relax in the short term and age in the long term, it is important to make sure that all specimens in a sample are capped at approximately the same time to minimize variability during testing.

For example, low-quality caps can result in blocked needles or needle seats due to coring. Maintenance tips. Ensuring continual maintenance can help with troubleshooting HPLC autosamplers, and should be done at least every 12 months. Components to consider include: - Needle and needle seat.

More than just a filling machine: it is a patented and fully validated filling process, based on a polymer vial with unique features Fact 2 The vial is closed before being filled: when produced, the AT-Closed Vial is molded and stoppered in ISO 5 environment, and when processed in the fill & finish suite, it is filled through the stopper