Jan 29, 2022 · Carefully check your medicine: Check the label. Make sure you have the right medicine. Check the date on the vial. Do not use medicine that is out of date. You may have a multi-dose vial. Or you may have a vial with powder that you mix with liquid. Read or ask about If you will use the medicine ...

Sep 1, 2017 · AST’s Vial Sealing Module (VSM) does just this. This machine module seals ready-to-use nested vials, but has designed out many of the common quality and process challenges that befall current system designs. Filled and stoppered vials transfer into the Vial Sealing Module where they are robotically placed into individual pockets on a starwheel.

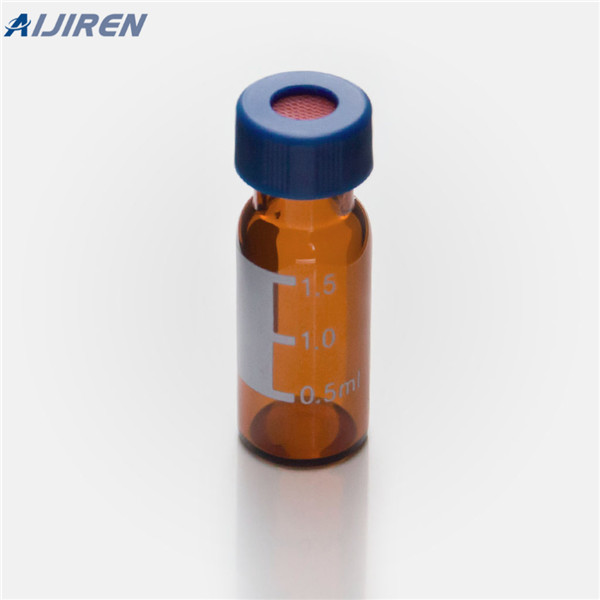

DetailsIncludes 2mL clear, pharmaceutical grade glass vials with write-on patch and fill marks and screw caps with matching threads for optimal vial sealing. Screw cap is knurled for excellent gripping and comfort. Fitted septa is manufactured with high grade PTFE/Silicone and is slit.This kit provides quality vials & caps. Vials and caps are packaged separately inside the kit which includes a

Quality Inspection for Vials During the Filling and Sealing Process. The VINSPEC HEALTHCARE inspection system covers all inspection requirements that apply to the filling and sealing of vials—inline, at filling speed. As a result, you can quickly detect unwanted process changes, correct the relevant parameter, and ensure high quality output

Testing Tips and Tricks. Reducing variability when testing residual seal force can be difficult to control. Since elastomeric vial seals relax in the short term and age in the long term, it is important to make sure that all specimens in a sample are capped at approximately the same time to minimize variability during testing.

and vial stoppers intended to be accessed with a needle or spike; plungers, needle shields, and tip caps for prefilled syringes or cartridges; components for pen, jet, and related injectors; lined caps for blow-fill-seal (BFS) plastic containers; and access ports to plastic bags or blow-molded infusion containers. 2.1 Package/Delivery Systems

Vial fillers are equipped with sensors that play a crucial role in quality control. These sensors detect and reject any vials that have not been properly filled, ensuring that only accurately filled vials proceed further in the process. To ensure uniformity and precision in filling, vial fillers incorporate a weight checker mechanism.

Sep 3, 2021 · A typical vial container closure system configuration has three major components: a vial, an elastomer stopper, and an aluminum seal with or without a flip-off button. 5 Among these container closure system components, the elastomer stopper plays a critical role by deforming to seal the vial-stopper interface area either temporarily or permanently.

1.1.2 Major Vial Defects 1.1.2.1 Major Non-Particulate Defects Vial Defect Classification = Major (Non-Particulate) Defect Type Example of Defect Closures Damaged or Missing Flip-Off Seal Volume Low Volume - for multi-dose vial, missing 25% or more of the required listed volume. Empty Vial 1.1.2.2 Major Particulate Defects

VIAL SEALING MACHINE PROTOCOL No.: 11.2 Evaluation of Performance: 11.2.1 Objective: To evaluate and to provide documented evidences for performance of equipment for proper sealing of filled vials. The objective of the test is to determine whether the machine is able to seal the Vial with aluminum seal properly. 11.2.2 Checks for machine:

DWK Life Sciences (Wheaton) crimp finish 12 x 32 mm With or without patch Color coded aluminum seals E-Z Vials and 11 mm Aluminum Seals are available assembled together in convenience packs of 100. These amber vials are made of Type 1 borosilicate glass. The aluminum seals are available in four colors:. Compare this item.

Jul 15, 2023 · A vial is a small, glass container, usually with a screw top lid and a rubber stopper used to seal the neck of the vial. Whereas ampoules contain only enough contents for one portion and are meant for one-time use, vials are larger, contain more product, and have a resealable lid. They may also have a dropper to extract the product.

I settled on making a solution of ketyl indicator in tetrahydrofuran, and dividing it among six vials that had cheap phenolic caps with coated paper liners. All had been stored for weeks inside

Jun 22, 2022 · Sealing station; The machine is currently designed to operate with 7.5 &10 ml tubular vials; Vial carriage system/ process flow; The vials are fed to the in-feed rotary table from the conveyer belt of the tunnel and fed to the conveyor belt. The vial is then sensed by a sensor so that the Aluminum Seal drooped over the neck having a rubber stopper.

Feb 1, 2016 · Morton et al. defined three major sealing areas of a closed vial [9]: first, the “land” seal formed between the vial sealing area and the rubber stopper closure flange (Fig. 3, no. 1); second, a “valve” seal along the inner vial neck and the rubber stopper plug (Fig. 3, no. 3); and third, a combination of the two seal types (Fig. 3, no